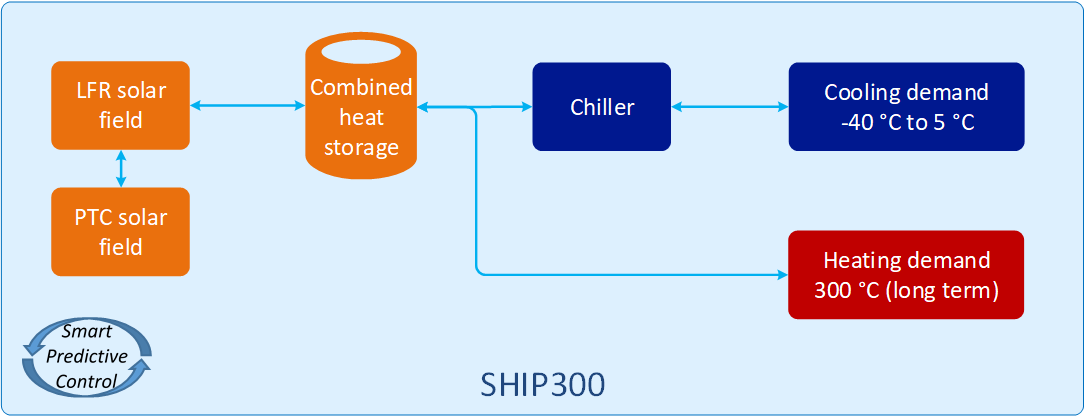

Two different systems SHIP200 & SHIP300 have been designed by consortium partners in order to address two different ranges of temperatures at the best price. For each system, a set of equipments will be developed and designed to optimize system performance to meet targeted heat and cold demand within relevant constraints. In the first concept, SHIP200, solar heat will be provided by low-cost PTCs with a maximum output temperature of 170-200°C. The coupling of the High Temperature Heat Pump and the Combined Heat Storage (a heat storage not only able to store heat from the solar loop, but from the process loop as well in case of excess heat in the process loop) will then boost the HTF temperature, store the heat and stabilize the delivery of heat for demand up to 180°C in a short-term development, and 250°C in the longer term. In parallel, some of the generated heat will be used to deliver cold from a chiller from 5°C down to -40°C. Special care will be taken in the development of a Smart Predictive Control of the system to ensure ease of operability and optimal payback time for future end-users.

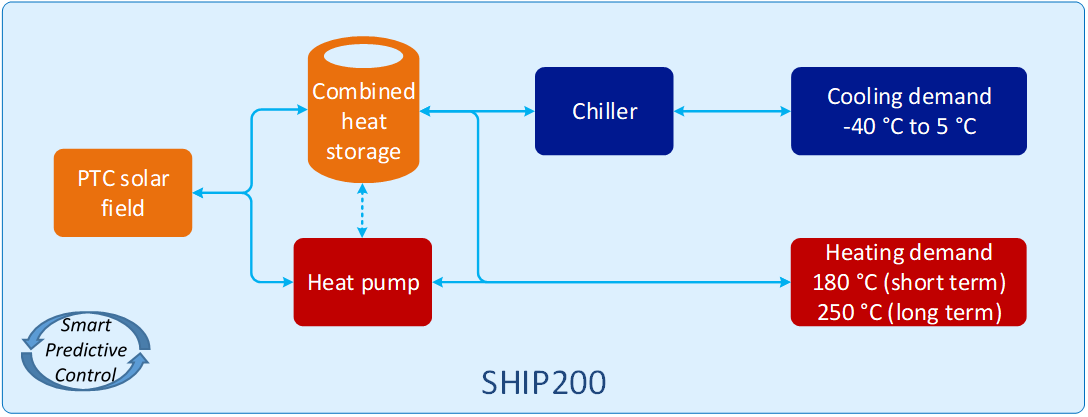

In the second concept, SHIP300 system, the High Temperature Heat Pump is replaced by an LFR field in order to boost the HTF temperature to higher temperature (280-300°C). This is necessary in order to address all types of processes used in the chemical industry. This higher source temperature will make mandatory to redesign the Chiller and the Heat Storage in order to reach the highest possible efficiency and thermal capacity. In this second option, the system will be obviously more expensive but dedicated to processes that demand higher heating temperatures.