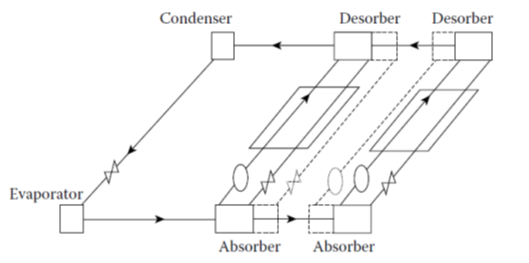

SINTEF and CEA are investigating different innovative solutions for absorption cooling at -20°C and -40°C from 100-250°C solar heat, in particular a GAX (Generator-Absorber heat eXchange) cycle based on commercial components, like Plate Heat Exchangers (PHE). This innovative design improves the heat and mass transfers, thus performance. In addition, manufacturing costs decrease, as the needed components are standardized and available in the market. A numerical study allows identifying the best solutions for the SHIP integration, giving an overview on the operating temperature ranges for each cycle. Thanks to these concepts, which led to the definition of technical sheets, a prototype of a GAX cycle for -20°C cooling will be realized, the choice on the final architecture will be made further on, when the market search will have provided the necessary economic data.

The work on the optimal design of the ejector chiller, targeting cold production down to 5°C (short term) and -10°C (long-term) is also being studied both on the process level and the component level. On the process level, SINTEF is working with the partners to optimize the cycle architecture and the choice of working fluid. On the component level, a detailed ejector model has been developed in a recently submitted publication. This model can for the first time can calculate the local entropy production through the ejector, which allows identifying the optimal ejector geometry as that which minimizes the entropy production.